Why Is Brannstrom Equipment Trusted in Maritime Operations?

January 20, 2026Oily water separators (OWS) keep bilge water within MARPOL limits by removing oil content before discharge. In Dubai, operators rely on compact, compliant monitoring like BilgMon 488 and the GBA-155 system to simplify MEPC 107(49) compliance and keep IOPP surveys smooth. This article explains how OWS work and why GBA-155 matters for Dubai fleets.

TL;DR / Key Takeaways

- Oily water separators remove oil from bilge water to meet MARPOL Annex I limits (typically 15 ppm for ships >400 GT).

- Dubai operators rely on compact, compliant monitoring like BilgMon 488 and advanced sensors (GBA-155) to simplify MEPC 107(49) compliance and IOPP surveys.

- Modern OWS technology combines centrifugal or gravity separation with smart monitoring (wireless, detachable cells) for easier maintenance in harsh UAE conditions.

- Regular calibration and proper documentation are essential for compliance during IOPP surveys and audits.

- Working with a Dubai-based provider (e.g., ghwasa.com) ensures regional service, parts and local regulatory alignment.

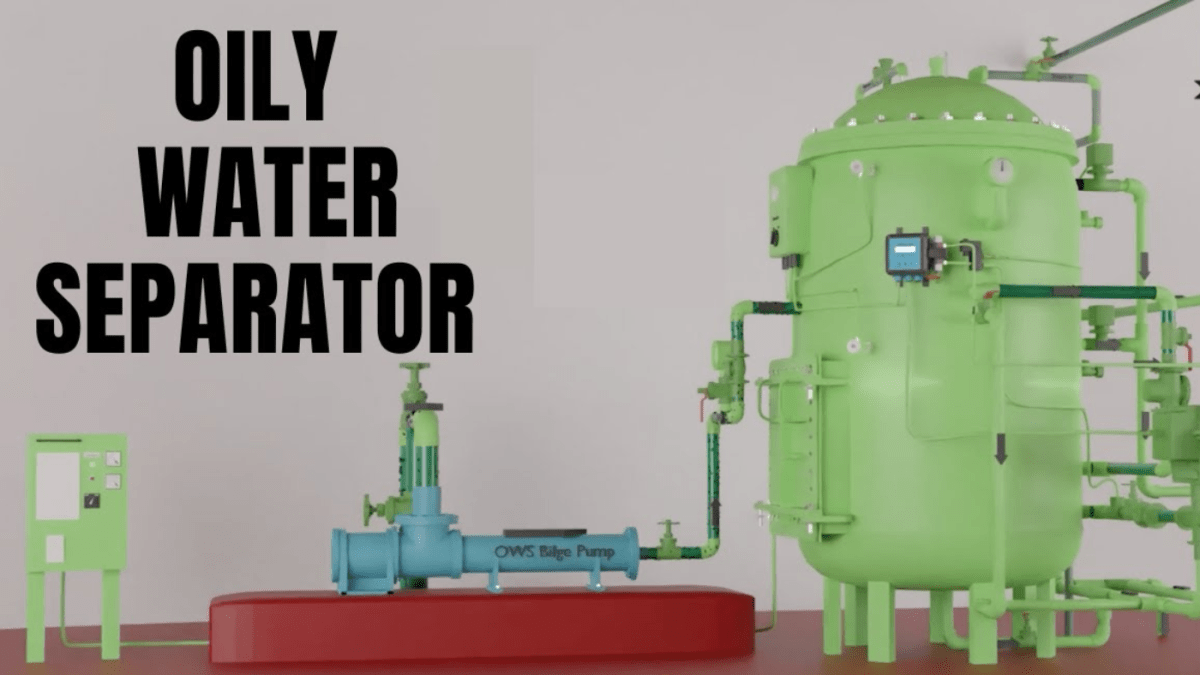

What is an Oily Water Separator (OWS) and Why It Matters in Dubai

OWS are engineered to separate oil from bilge water and discharge only within regulatory limits.

Definition: An OWS uses either centrifugal or gravitational forces to strip oil and allows clean water to meet the 15 ppm limit on ships over 400 gross tons. In Dubai’s busy ports, an effective OWS helps vessels avoid pollution penalties and supports sustainable operations. For UAE operators, reliable OWS plus continuous monitoring reduces survey risks and keeps port state control happy. MARPOL Annex I sets the baseline while MEPC updates tighten monitoring expectations.

How OWS Works: Step-by-Step Operational Process

- Bilge water intake from the vessel’s bilge system collects mixed fluids for treatment.

- The separation stage uses centrifugal or gravity separation to separate oil from water.

- Oil layer management oil-contaminated water is redirected or discharged under limits.

- Monitoring and control oil content monitors, alarms and data logging track performance.

- Discharge verification documentation is prepared for compliance and surveys.

OWS Technologies and the Dubai Market (What’s New in 2026)

OWS technology blends separation methods with smart sensors. Centrifugal vs gravity separation offers different trade-offs in speed, space and efficiency. Notable models include:

- Alfa Laval PureBilge (centrifugal): high performance in compact packages.

- BilgMon 488 bilge alarm (15 ppm standard 5 ppm option): wireless, compact, retrofit-friendly.

- OWS retrofit options like OWS-PT to ease integration on UAE vessels.

Dubai-specific relevance includes local service, parts and regulatory alignment from regional partners. This helps meet MEPC.107(49) compliance and prepares ships for IOPP surveys. BilgMon 488 is designed to work with GBA-155 for enhanced monitoring. The GBA-155 interface improves data capture and enables flexible maintenance, even in harsh climates.

Regulatory Landscape: MARPOL Annex I MEPC.107(49) and UAE Implications

Key rules drive OWS choices. MARPOL Annex I requires oil content in bilge water discharge to stay below limits. Oil Content Monitors (OCMs) and bilge alarms are standard on ships over 400 GT. MEPC.107(49) adds monitoring and reporting expectations. In the UAE enforcement is strict and IOPP surveys are common. Some installations carry a Clean Design notation with a 5 ppm option for tighter controls. IMO guidance informs local practice.

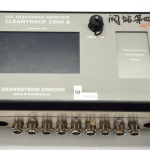

Why BilgMon 488 and GBA-155 Matter for Dubai Operators

The BilgMon 488 helps meet MARPOL 15 ppm with a 5 ppm Clean Design option. Wireless, detachable measuring cells simplify calibration and maintenance. Dubai ready retrofits fit existing OWS packages without major overhauls. The GBA-155 enhances monitoring with better data access and streamlined calibration workflows. Dubai service support from ghwasa.com ensures quick parts and local expertise, critical for IOPP survey readiness.

Maintenance, Calibration and Compliance in the UAE

Calibration cadence follows manufacturer guidance and survey requirements. Keep certificates aboard for IOPP readiness. In Dubai’s heat and salinity, regular maintenance targets dust, corrosion and battery health. Wireless or detachable components reduce downtime and simplify spare-part planning.

Real-Life Use Case: Dubai Vessel Upgrade with BilgMon 488 and GBA-155

Scenario: A Dubai-based vessel retrofit to meet MEPC 107(49) and 15 ppm limits. The steps taken included a site assessment, BilgMon 488 installation with wireless 0–30 ppm monitoring, and GBA-155 integration for enhanced data capture. Calibration was validated and IOPP survey readiness achieved. Outcomes: improved MARPOL compliance, reduced maintenance downtime and a clear audit trail. Local support from ghwasa.com enabled fast parts delivery and on site service.

Quick Model and Capability Comparison (Dubai-focused)

- BilgMon 488 (15 ppm; 5 ppm option): Retrofit-friendly, wireless, easy calibration.

- Alfa Laval PureBilge: High separation efficiency, reliable but larger footprint.

- OWS-PT retrofit: Simplifies installation in tight dockside spaces.

Choosing for a Dubai fleet depends on vessel size, bilge flow, retrofit feasibility, service availability and regulatory alignment. The goal is a system that stays compliant with MARPOL and MEPC while minimizing downtime.

Benefits of Owning and Maintaining an Integrated OWS System in Dubai

- Environmental protection: Reduces oil pollution and safeguards marine habitats.

- Regulatory compliance: Supports MARPOL Annex I limits and MEPC 107(49) expectations.

- Operational efficiency: Wireless, detachable components simplify upkeep.

- Cost considerations: Retrofit ease, reduced downtime, long-term maintenance savings.

- Local support: Dubai-based service networks for installation and updates.

Real-Life Example or Use Case Section (Dubai)

Dubai-anchored fleets often retrofit BilgMon 488 with GBA-155 to align with MEPC 107(49). This reduces downtime, improves data accuracy and provides a robust audit trail for authorities. Local support from ghwasa.com helps with site assessments, parts supply and post-installation service.

Conclusion and Next Steps

OWS technology, regulatory context and Dubai-specific considerations protect marine environments while easing compliance. Operators should assess current bilge monitoring, engage with a Dubai-based provider for BilgMon 488 and GBA-155 integration, and plan calibration and IOPP survey readiness. Contact ghwasa.com for a site assessment and a formal compliance roadmap.

Glossary (optional)

- OWS: Oily Water Separator

- MARPOL Annex I: International oil pollution rules

- MEPC 107(49): IMO amendments on OWS monitoring

- OCM: Oil Content Monitor

- IOPP: International Oil Pollution Prevention survey

- Clean Design: stricter design/monitoring notation

- GBA-155: Advanced bilge monitoring sensor system

- BilgMon 488: 15 ppm bilge alarm with 5 ppm option

FAQ

What is the standard oil discharge limit for ships over 400 GT?

15 ppm, per MARPOL Annex I.

Can I upgrade to a 5 ppm Clean Design notation?

Yes, BilgMon 488 offers a 5 ppm option.

How often must OWS calibration be checked?

Manufacturer guidelines and IOPP survey requirements govern calibration intervals.

What is the role of GBA-155 in OWS setups?

GBA-155 provides enhanced monitoring and data management for oil content.

Is there Dubai-specific service support for BilgMon 488?

Yes, local distributors in Dubai offer installation and maintenance.

How do size and maintenance affect IOPP survey readiness?

Proper sizing, calibration and documentation are critical for surveys.